How Is LCD Monitor Sheet Metal Manufactured for Industrial Display Applications?

2025-12-31

LCD Monitor Sheet Metal refers to precision-fabricated metal enclosures and structural components used to house, protect, and support LCD display panels across industrial, commercial, and professional environments. This article provides a comprehensive examination of how LCD Monitor Sheet Metal is engineered, manufactured, and optimized to meet durability, thermal management, electromagnetic shielding, and aesthetic requirements. The central objective is to clarify how material selection, structural design, and fabrication parameters directly influence display reliability, lifecycle performance, and scalability in modern display systems.

Abstract

LCD Monitor Sheet Metal plays a critical role in ensuring structural integrity, heat dissipation, and environmental protection for display systems. This document analyzes manufacturing workflows, material specifications, dimensional tolerances, and industry use cases while addressing common technical questions. It also examines how evolving display technologies influence enclosure design trends and production standards.

Table of Contents

- Outline

- How Are Materials Selected for LCD Monitor Sheet Metal?

- How Do Technical Parameters Define Product Performance?

- How Does the Manufacturing Process Ensure Consistency?

- How Is LCD Monitor Sheet Metal Applied Across Industries?

- LCD Monitor Sheet Metal Common Questions

- How Will LCD Monitor Sheet Metal Evolve in the Future?

Outline

The article is structured into four integrated sections: material engineering fundamentals, technical parameter analysis, manufacturing and quality control, and application-driven design trends. Each section builds upon the previous to provide a logical and technically grounded narrative.

How Are Materials Selected for LCD Monitor Sheet Metal?

Material selection is the foundation of LCD Monitor Sheet Metal design. Commonly used materials include cold-rolled steel (SPCC), galvanized steel (SGCC), aluminum alloys (5052, 6061), and stainless steel. Each material is chosen based on mechanical strength, corrosion resistance, weight constraints, and thermal conductivity.

Aluminum alloys are frequently applied in high-end or portable display systems due to their lightweight nature and superior heat dissipation. Steel-based enclosures are preferred for fixed industrial installations where rigidity, impact resistance, and cost efficiency are prioritized. Surface treatments such as powder coating, anodizing, or electrophoretic coating further enhance durability and visual uniformity.

How Do Technical Parameters Define Product Performance?

Technical parameters establish the functional boundaries of LCD Monitor Sheet Metal and determine compatibility with display modules, mounting systems, and operating environments. Precision control over these parameters ensures repeatable performance across production batches.

| Parameter | Typical Range | Technical Significance |

|---|---|---|

| Material Thickness | 0.8 mm – 2.5 mm | Balances structural rigidity and weight control |

| Dimensional Tolerance | ±0.1 mm – ±0.2 mm | Ensures precise LCD panel alignment |

| Surface Roughness | Ra ≤ 1.6 μm | Improves coating adhesion and appearance |

| EMI Shielding | 30–60 dB | Reduces electromagnetic interference |

How Does the Manufacturing Process Ensure Consistency?

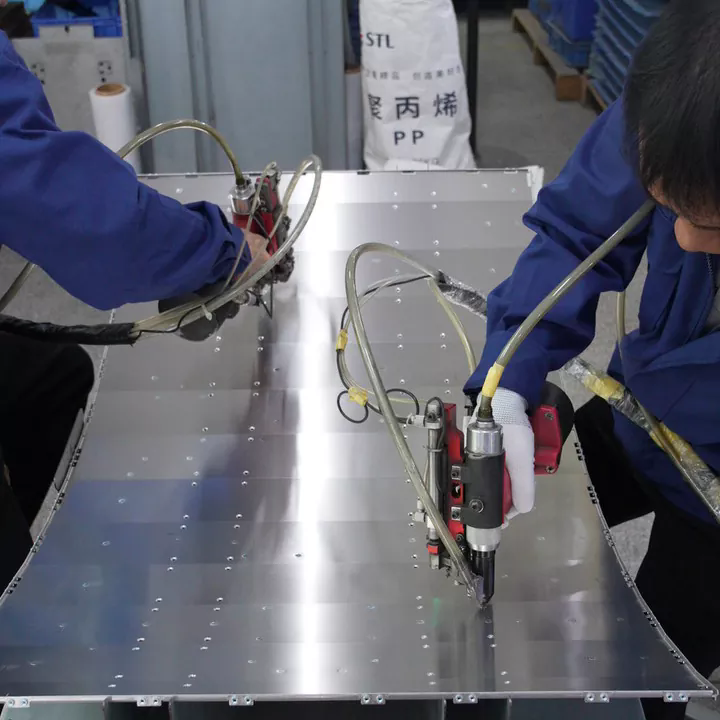

LCD Monitor Sheet Metal manufacturing involves a sequence of controlled processes, including laser cutting, CNC punching, bending, welding, surface finishing, and assembly. Laser cutting ensures high-precision edge quality, while CNC bending machines maintain angular consistency across complex geometries.

Quality assurance protocols typically include first-article inspection, in-process dimensional verification, and final functional checks. These measures minimize cumulative tolerances and ensure compatibility with LCD panels, backlight units, and electronic assemblies.

How Is LCD Monitor Sheet Metal Applied Across Industries?

LCD Monitor Sheet Metal is widely used in industrial automation panels, medical imaging displays, transportation control systems, retail digital signage, and outdoor information terminals. Each application imposes distinct requirements related to ingress protection, vibration resistance, and thermal stability.

For example, outdoor digital signage requires weather-resistant coatings and reinforced structures, while medical-grade displays prioritize smooth surfaces and precise sealing to support hygiene standards.

LCD Monitor Sheet Metal Common Questions

Q: How does sheet metal design affect LCD heat dissipation?

A: Proper ventilation patterns, material conductivity, and structural spacing allow heat generated by backlight and electronics to dissipate efficiently, reducing thermal stress and extending display lifespan.

Q: Can LCD Monitor Sheet Metal be customized for different panel sizes?

A: Yes. Modular design principles and flexible tooling enable customization for various screen dimensions, mounting standards, and interface layouts without compromising structural integrity.

Q: What determines the durability of LCD Monitor Sheet Metal?

A: Durability depends on material grade, thickness, surface treatment, and welding quality, as well as compliance with environmental and mechanical testing standards.

How Will LCD Monitor Sheet Metal Evolve in the Future?

As display technologies continue to advance toward thinner profiles, higher resolutions, and increased integration, LCD Monitor Sheet Metal design is expected to emphasize lightweight structures, multifunctional components, and sustainable materials. Smart manufacturing techniques and digital simulation will further optimize enclosure performance and production efficiency.

In this evolving landscape, Xinyang continues to focus on precision fabrication, material innovation, and application-driven engineering to support global display manufacturers and system integrators. Organizations seeking reliable LCD Monitor Sheet Metal solutions are encouraged to evaluate design compatibility, production capability, and long-term quality assurance. For detailed specifications or project discussions, contact us to explore tailored solutions.